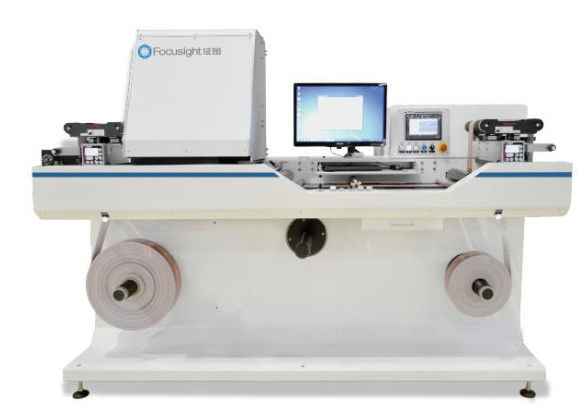

Double Side Printed Tag Quality Inspection System With Fully Suction Platform

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-GECKO-200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Maximum Size: | 200mm × 300mm | Minimum Size: | 40mm × 70mm |

|---|---|---|---|

| Speed: | 150m/min | Power: | 10KW |

| Paper Weight: | 150 ~ 350 GSM | Machine Mechanical Size: | 3650mm (L) × 1000mm (W) × 1500mm (H) |

| Machine Weight: | 2Tons | ||

| High Light: | printing inspection machine,quality control equipment |

||

Product Description

Upto 200mm Size Double Side Printed Tag Quality Inspection System, with Fully Suction Platform

Product Technical Specification-FS200-GECKO-P2N2

Full machine configuration

| Project | Configuration instructions | Number | Description of the function | -Select | |

| Detection system configuration | Front direct-shooting station | Imported high-speed RGB color 4096 pixel scan camera | 1 | General printing defects , die-cutting, Commodity code | √ |

| Imported optical imaging lens | 1 | √ | |||

| Dedicated bar light source . | 1 | √ | |||

| High-speed image processing computer workstation (high-speed image capture processing card)) | 1 | √ | |||

| Front angled position | Imported high-speed 4096 cell-line scanning camera | 1 |

Light oil bias, missing Convex oil bias, missing Embossed bias

|

√ | |

| Imported optical imaging lens | 1 | √ | |||

| Dedicated Oblique Light Source . | 1 | √ | |||

| High-speed image processing computer workstation (high-speed image capture processing card)) | 1 | √ | |||

| Reverse direct-shooting station | Imported high-speed RGB color 4096 pixel scan camera | 1 |

General printing defects die-cutting bias Commodity code |

√ | |

| Imported optical imaging lens | 1 | √ | |||

| Dedicated bar light source. | 1 | √ | |||

| High-speed image processing computer workstation (high-speed image capture processing card)) | 1 | √ | |||

| Reverse reflection station | Imported high-speed 4096 cell-line scanning camera | 1 |

l Convex oil bias, missing l embossed bias

|

√ | |

| Imported optical imaging lens | 1 | √ | |||

| Dedicated Reflection Light Source. | 1 | √ | |||

| High-speed image processing computer workstation (high-speed image capture processing card)) | 1 | √ | |||

| Detection of software configurations | Print inspection module dedicated vision inspection software FSCheck V2.1.1 | 1 | √ | ||

| Mix detection module | 1 | Mixed code | √ | ||

| Defect Detection Statistics Report | 1 | Document reports that count the types and numbers of defects | √ | ||

| Detection of supporting equipment | Special dust-removal closed electric cabinet for printing detection | 1 | Protection detection devices and partial dust protection | √ | |

| 22-inch LCD and keyboard mouse | 1 | √ | |||

| Sound and light alarm device | 1 | √ | |||

| Rear display | 1 | √ | |||

| Mechanical platform configuration | Mechanical transmission platform structure configuration | Friction card issuer | 1 | √ | |

| Note: double-sided water-based photooil or film class, such as scratch-prone products are not within the scope of this specification agreement; | |||||

| Electrostatic dust removal device | 1 | √ | |||

| Fish scale syield collection mechanism | 1 | √ | |||

| Fish scale satosing collection facility | 1 | √ | |||

| Replica Reject Ingesta (Note 1) | 1 | √ | |||

| Electrical support ingen-care system | 1 | √ | |||

| Strong electrical components of mechanical platforms | German SEW main motor | 1 | 4KW Supply Host Main Drive Power | √ | |

| German SEW paper transfer motor | 1 | 1.5KW supply paper cloth set drive power | √ | ||

| Pump | 2 | 2 units of4KW | √ | ||

| Collectthe motor | 1 | 0.4KW | √ | ||

| Waste-receiving motors | 1 | 0.4KW | √ | ||

Note 1: This transmission system requires the user to provide a factory concentrated gas source or an external air compressor for equipment scrap removal.

2.3 Device function parameters

| Project | Function parameters |

| Maximum detection speed | 150 / |

| Maximum detection size | 200mm )x300mm(length)( length is more than 140mm,host speed needs to be reduced appropriately) ) |

| Minimum detection size | 40mm )x70mm(length) |

| Adapting to paper weight | 150to350g/m2 |

| Field of view | 220mm |

| Imaging accuracy (mm) |

Front imaging accuracy (direct-shooting station):0.054mm x 0.075mm(4K camera) Front imaging accuracy (oblique station):0.054mm x 0.15mm(4Kcamera) Reverse imaging accuracy (direct-shooting station):0.054mm x 0.075mm(4K camera) Reverse imaging accuracy (reflected station):0.054mm x 0.15mm(4Kcamera) |

| General defect detection (when defect contrast is greater than 40 levels) |

1. Minimum detection area of defects such as leakage, dirty points: s0.15 mm2 2. Minimum detection area of hot burn defects: .2mm2 3. Overprint bias detection:.1mm 4. Die-cutting deviation detection:.1mm 5. Pull line: can detect a horizontal or vertical pull line that is wider than 0.1mm vertical, or 0.2mm wide horizontal, more than 15mmin length, and a contrast greater than 40 levels; 6. Local Chromatic Abercheck Detection , E-3ELab |

| Mechanical profile size | 3.65m x 1mx1.49m (L * W * H) standard |

| Equipment footprint | 3.65m x 2mx1.8m (L * W * H) |

| Mechanical weight | 2 tons |

| Full machine power | 10KW |

Inside Pictures:

![]()

![]()

![]()