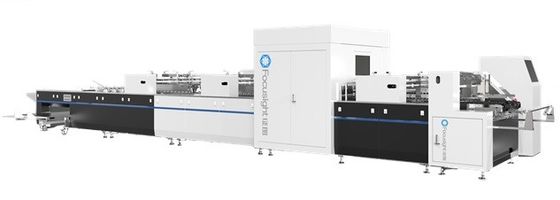

220m / Min Quality Control Vision Systems For Rigid Box Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-1100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Maximum Size: | 1100mm * 900mm | Minimum Size: | 400mm * 300mm |

|---|---|---|---|

| Speed: | 220m / Min | Power: | 28kw |

| Paper Weight: | 200 ~ 650 GSM | Machine Mechanical Size: | 9500mm (L) * 3300mm (W) * 2000mm (H) |

| Machine Weight: | 8 Tons | ||

| High Light: | industrial vision system,printing inspection machine |

||

Product Description

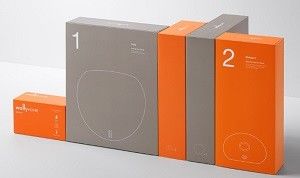

Focusight Rigid Box Production line Inspection System for Bigger Size 1100mm Cartons

PROPOSAL

BIG SHEET HIGH SPEED QUALITY INSPECTION MACHINE FS-SHARK-N1100

Technical Part

Product Description

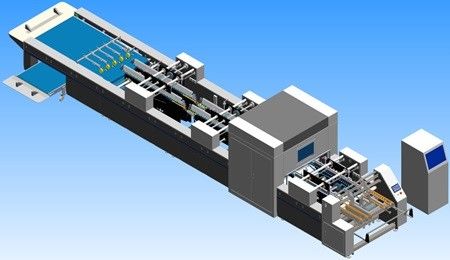

What: The Focusight Inspection Machine will precisely find out the defects of printing on presswork and reject the bad ones from the good ones automatically.

How: The Focusight cameras scan some good presswork as “STANDARD” and then while the rest of the printed jobs are inspected be scanned one by one and compared with the "STANDARD", any mal-printed or defective ones will be rejected automatically by the system. It detects every type of printing or finishing fault – color misregistration, color variations, hazing, misprints, defect in the text, spots, splashes, varnishing missing & misregistration, embossing missing & misregistration, laminating problems, die-cut problems, barcode problems, Holographic Stripe, cure & cast and many other printing problems.

Object of Inspection

Form 1: the kind of Detectable Objects on Big Sheet

Note : ( ★ Detectable; ☆ Partially Detectable; △ Undetectable )

| Product Type | FS-SHARK-N1100-P1 | FS-SHARK-N1100-P2 | FS-SHARK-N1100-P2N1 |

| Applicable Presswork | FBB, SBS paperboard, Offset paperboard, Coated free sheet paper , Gold or Silver coated paperboard, Laser paperboard | ||

| Regular Printing | ★ | ★ | ★ |

| Color Misregistration & Variation | ★ | ★ | ★ |

| Die Cutting Misregistration | ★ | ★ | ★ |

| Foil Stamping | ★ | ★ | ★ |

| Holographic Stripe | ★ | ★ | ★ |

| Variable Barcode & QR code | ★ | ★ | ★ |

| Laminating | △ | ★ | ★ |

| Vanishing Misregistration | △ | ★ | ★ |

| Vanishing Missing / Scratch | △ | ★ | ★ |

| Convex Oil Misregistration | △ | ★ | ★ |

| Convex Oil Missing / Scratch | △ | ★ | ★ |

| Embossing Mis registration | △ | ★ | ★ |

| Silkscreen | △ | ★ | ★ |

| Scratch | ☆ | ★ | ★ |

| Reverse Side big defect | ★ | ★ | ★ |

Technical Parameter

Form 2: Performance Parameters of Inspection System

| Product Type | FS-SHARK-N1100-P2N1 |

| Inspection FOV | 1100mm (Width) |

| Imaging Resolution (mm) |

Front Imaging Resolution (Regular Printing Side): 0.15mm * 0.12mm (7k color camera) |

| Regular Printing (when the defect contrast is over grade 40) |

1. Minimum Inspection Area of Regular Defects, such as Printing Missing, Dirty Spot and stuff like that: ≥0.3 mm 2 |

Form 3 : Performance Parameters of Transportation Platform

| Item | Parameter |

| Max. Transportation Speed | 220m / min |

| Max. Sheet Dimension (W * L) | 1100mm × 900mm |

| Min. Sheet Dimension (W * L) | 400mm × 300mm |

| Suggested carton Gram Weight | 200 ~ 650g / ㎡ |

| Suggested corrugate Weight | B, EF type |

| Total Mechanical Platform Dimension (L * W * H) | 9500 mm × 3300 mm × 2000 mm |

| Total power | 28kw |

| Total Weight | 8 Tons |

Commercial Part

- Delivery Time

- The time of delivery to Shanghai Port shall be 70 days after receipt of down payment and technical approval both, which may be postponed accordingly due to the late payment, or delay of technical approval, or any amendment caused by the Buyer.

- Installation

- Installation of the machine will be done by our engineers (one mechanical engineer and one software engineer). Installation and training is free of charge and the whole period is about 16 working days.

- Customer is also responsible for hotel accommodation (3 star hotel), meals and local transportation for engineers.

- Warranty

- There is 1 year warranty (from the date of installation) on all parts, mechanical, electrical and software due to defect in manufacturing, except for consumable parts such as belts, rubber sucker, etc and if “accident” or mal-operation has occurred .